Steecker

Until now, the industrial culture of our industry has defined the limits of the possible. Our innovation comes from an act of criticism of what is existent and from a vision of what is still non-existent. Steecker is not only something new, but it is also the base for a change intended to have long-term consequences. Steecker changes the limits of what is possible.

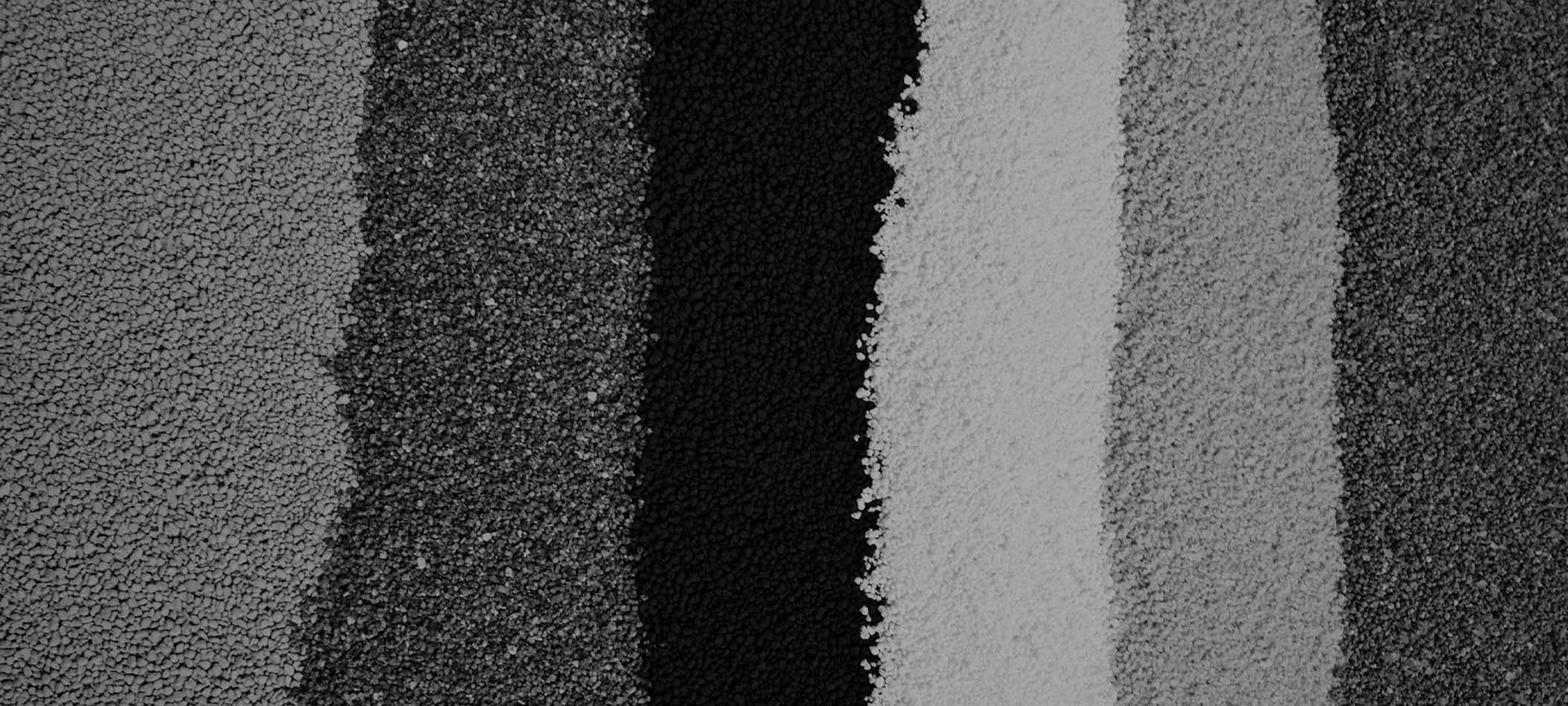

The use of powder in the animal feed sector introduces the problem of low flowability.

Steecker granulation technology increases the particle size of raw materials and of semi-finished products such as premix and complementary feedstuff:

this means an improved flowability and easier measuring out compared to powder.

Steecker technology is an example of particle design. The desired result of granules is the perfect combination between the intended use, the user, the chemical formulation and the industrial process. By following this path, Steecker reaches high standards of uniform shape and size of granule. Sizes can be designed and produced from a minimum of 0.7 mm to a maximum of 1.5 mm.

Form is substance

We enhance performances which are not provided by compositions. Steecker technology joins shape characteristics with composition characteristics (“performance”) to obtain products with higher quality standards than other industry products, which meet customer needs beyond the limits of the possible.

The larger size and higher density of Steecker granules (compared to an equal volume of powder), reduce the surface area exposed to atmospheric agents such as moisture, thus protecting the active principles from oxidisation processes.

Each raw material has its own specific gravity. The diversity of specific gravities is the cause of separation among different components of powder. The micro Steecker granule has one specific gravity because it is a stable and permanent aggregate of diverse particles.

Thanks to Steecker technology, each granule maintains its different active ingredient particles united. Steecker granules are stable, homogeneous and permanent masses in which the original particles can still be distinguished.

Performance

Steecker products are made in a unique facility which was designed and constructed according to particular specifications defined by R&D Farmer S.p.A. in collaboration with the Faculty of process engineering and engineering companies. Thanks to fully automated process control, certifications and quality control, Farmer S.p.A. guarantees the excellence of processes and finished products.

In comparison with powder feedstuff, Steecker micro granules do not involve inhalation hazards as they are not suspended in the air, whereas fine powder has a high suspension time of small particles with the possibility that the operator could inhale large amounts of the substance.

Steecker micro granules do not disperse dust thanks to their structure and unifying force, so the contact area with a granule is lower than with the equivalent volume of powder.

Electrostatic charging occurs when solids move in relation to the materials with which they are in contact. Compared to powder, the volume and density of a Steecker granule present greater resistance to attraction generated by electric charges which are present in the interface of materials. (e.g. mixers, augers, etc.).

Steecker micro granules have a higher porosity than that of powder particles: this facilitates the penetration of fluids inside the pores with a subsequent improved dissolution of active ingredients in a slower way.

The certainty of no loss of product due to mechanical and environmental effects is guaranteed by the texture of Steecker micro granules, which slide out from packaging and storage, due to its ability to blend evenly without separating, the absence of dust and its ability to withstand electrostatic charges.